Robotic Technologies

When planning for an automated cell, there are many options and accessories that can be added to help reduce cycle time and increase efficiency. Productivity will evaluate your processes to determine the best options and accessories to integrate into your cell.

Some of the robotic technologies we utilize include:

High Speed Servo Door

We can equip your machine with a high speed servo door opener that allows most machine doors to be opened or closed in just one second – much more quickly than your typical pneumatic door. A manual control operates the door at a slower and protected speed. Upon contact with an obstacle, the servo door opener reverses the closing motion and stops the door cycle.

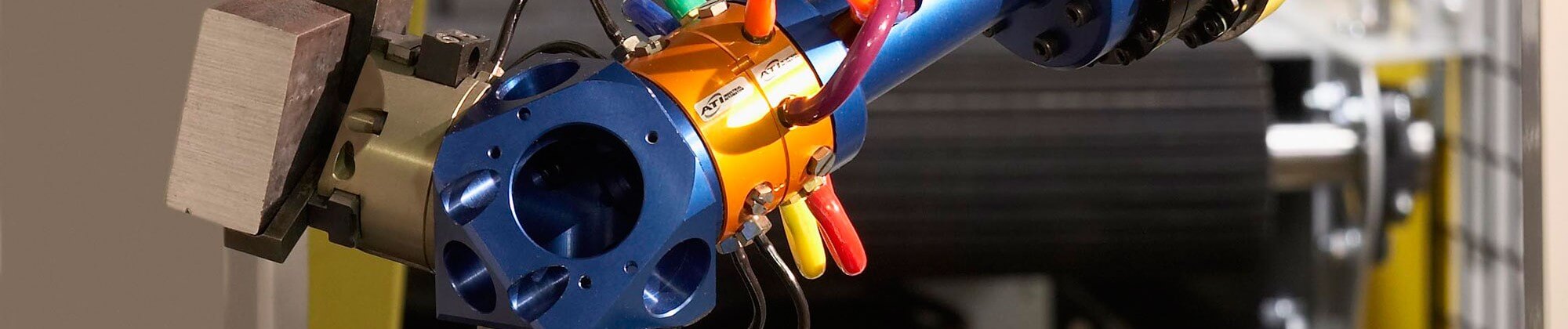

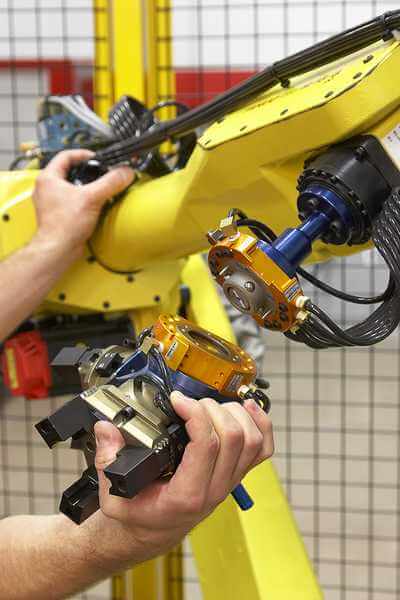

Quick Change Gripper Mount

This option allows the operator to change gripper head assemblies in just seconds. The quick gripper mount contains couplings for up to three gripper heads and eliminates the need to change screws, gripper fingers and air lines. When used on a system that will be changed over frequently, it will improve uptime and consistency of set-ups and shorten the changeover time.

High Pressure Coolant (HPC) System

An HPC system can increase feeds and speeds, as well as provide chip control. With the higher cooling and lubricating power of an HPC system, the machine tool can run at a higher surface speed and utilize its full power capacity. Increased pressure of coolant hitting the chips makes them easier to break and flush away from the work piece. An HPC system can decrease down time, increase tool life and reduce tool breakage.

Air Blow Unit

This unit bolts inside of the machine tool to allow the system to command air blow off the part locating device.

Extra Blank Pallets

These blank pallets come ready to have new part nest pockets milled into them. They drop onto the receiver pins of the rotary unit on the pallet switcher turntable.

Part Re-grip Station

The part re-grip station provides a quick change base that can accommodate a variety of small fixtures a robot may require in dual side operations. The quick change base is always in the same location and makes it easy for part changeover as it eliminates the need to re-teach the part re-grip portion of the material handling program. The part re-grip station allows any part that fits into a 4-inch cube to be set down and re-gripped for a second side operation. NOTE: The actual part cradle is part-specific and must be provided by the customer.

Part Inspection Chute

This option allows an operator to push a button to request the next part to be unloaded to the chute rather than the pallet return nest. This allows for real-time inspection of the latest part rather than interrupting the pallet load or automatic cycle.

Part Gauging Station

Part inspection stations can be incorporated into the cell. Because inspection needs are complex and vary widely, we must evaluate each situation individually.

Robotic Vision System

This reliable system allows operators to randomly place parts onto the in-feed conveyer. The vision system identifies and transmits the part coordinates to the robot for pick-up. This makes the introduction of new parts more flexible and reduces the amount of special hardware required to orient and separate incoming parts for pick-up.

Part Marking

Part marking systems, such as pin markers, ink jets or laser markers, can be incorporated into the cell.

Miscellaneous Parts and Accessories

Other available components include faceplate stems, master quick change plates, tool plates, gripper mounts, 3-jaw grippers and spare gripper jaws.