Services and Support

Maximize Efficiency and Longevity with Our Comprehensive Service and Preventative Maintenance

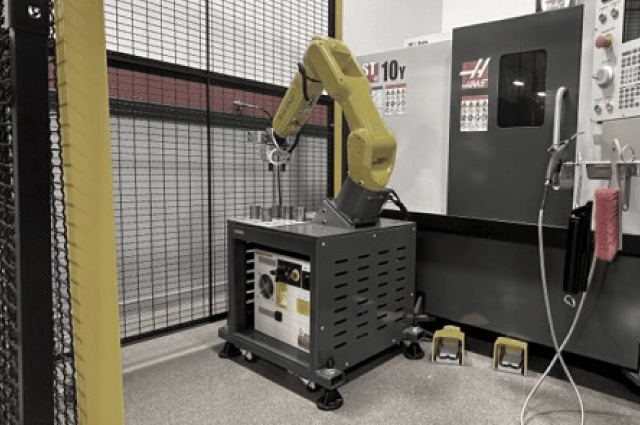

Enhance the performance and extend the lifespan of your industrial robots and collaborative robots (cobots) with our expertly designed service and preventative maintenance. Our team of automation and robotics engineers, specializing in CNC optimize operational efficiency and minimize downtime. As leaders in CNC integration and automation, we offer tailored service plans that meet your specific needs, ensuring your equipment remains in peak condition. Servicing across the US—we guarantee a swift response and expert care wherever your operations are based.

OUR SERVICES

TECHNICAL PHONE SUPPORT

Immediate expert assistance is just a call away. Our specialized technicians provide real-time troubleshooting and guidance, minimizing downtime and resolving issues promptly.

TROUBLESHOOT

Using advanced diagnostic tools and methodologies, we swiftly identify and resolve complex issues. Our approach combines remote analysis with on-site inspections to ensure comprehensive problem-solving.

REPAIR

Our skilled technicians perform both emergency repairs and scheduled maintenance. We use OEM parts and cutting-edge repair techniques to restore your robots to peak condition quickly and effectively.

PREVENTATIVE MAINTENANCE

Our preventative maintenance plans are tailored to your specific robotic systems and production environment. These plans include:

• Calibration and alignment checks

• Lubrication and cleaning of critical components

• Detailed reporting and recommendations for system optimization

By choosing our service and preventative maintenance team, you’re not just maintaining robots; you’re ensuring the continuous evolution and peak performance of your CNC automation systems. Our expertise keeps you at the forefront of manufacturing technology, driving productivity and maintaining your competitive edge.

RELATED SOLUTIONS