Abrasive Waterjet Cutting

What is Abrasive Waterjet Cutting?

An abrasive waterjet cutting machine uses a narrow stream of high-pressured water with abrasive particles such as garnet added to the nozzle or cutting head to cut almost any material type and thickness. Waterjet cutting is basically a supersonic erosion process, spraying out water at a rate upwards of 60,000 psi. Because the abrasive is added at the nozzle, it is simple to switch between water only and abrasive waterjet cutting, to easily switch materials being cut.

An abrasive waterjet cutting machine uses a narrow stream of high-pressured water with abrasive particles such as garnet added to the nozzle or cutting head to cut almost any material type and thickness. Waterjet cutting is basically a supersonic erosion process, spraying out water at a rate upwards of 60,000 psi. Because the abrasive is added at the nozzle, it is simple to switch between water only and abrasive waterjet cutting, to easily switch materials being cut.

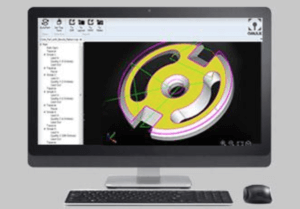

An abrasive waterjet cutting machine has several basic components — a cutting table, x-y traverse system, a water jet cutting head nozzle, a high-pressure pump and a PC-based controller. Unlike other waterjet systems, all OMAX systems come with IntelliMAX software. This advanced control software can automatically program the cutting path of a desired part directly from a CAD drawing. The results are optimized cutting, enhanced performance and reductions in total cut times all while increasing overall machining speed.

An abrasive waterjet cutting machine has several basic components — a cutting table, x-y traverse system, a water jet cutting head nozzle, a high-pressure pump and a PC-based controller. Unlike other waterjet systems, all OMAX systems come with IntelliMAX software. This advanced control software can automatically program the cutting path of a desired part directly from a CAD drawing. The results are optimized cutting, enhanced performance and reductions in total cut times all while increasing overall machining speed.

Why Waterjet Cutting Equipment?

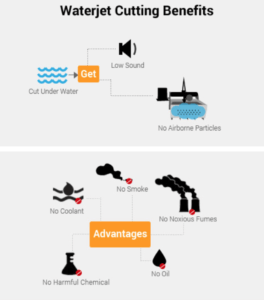

High-pressured water cutting systems provide many advantages, including fast setup, easy programming, high cutting speeds, narrow, precise cuts, an ability to produce consistent cuts time after time, no heat-affected zones (HAZ), low cutting forces, and therefore minimal fixturing. In addition, unlike other traditional methods, waterjet can reduce kerf, allowing parts to be positioned or nested closer together resulting in overall savings on materials which is particularly important when working with expensive materials such as titanium, alloy steel and the like.

High-pressured water cutting systems provide many advantages, including fast setup, easy programming, high cutting speeds, narrow, precise cuts, an ability to produce consistent cuts time after time, no heat-affected zones (HAZ), low cutting forces, and therefore minimal fixturing. In addition, unlike other traditional methods, waterjet can reduce kerf, allowing parts to be positioned or nested closer together resulting in overall savings on materials which is particularly important when working with expensive materials such as titanium, alloy steel and the like.

Depending on the equipment model and stock material, it is possible to cut through 1/16 inch to over 10 or 12 inches of material thickness. Abrasive waterjet cutters can pierce through virtually any material, from metal and nonmetal, carbon fiber to copper, glass to granite, titanium to tungsten and practically anything in between.

Depending on the equipment model and stock material, it is possible to cut through 1/16 inch to over 10 or 12 inches of material thickness. Abrasive waterjet cutters can pierce through virtually any material, from metal and nonmetal, carbon fiber to copper, glass to granite, titanium to tungsten and practically anything in between.

Given these advantages, an abrasive waterjet cutting machine is an ideal complement to any machine job shop whose business is devoted to machining processes such as milling, turning, grinding and more. You can count on the waterjet process for a myriad of applications including precision prototyping, short-run jobs, multiple parts from stacks of material, and complex cutting operations, to name a few.

Productivity Waterjet Cutting Machine Suppliers

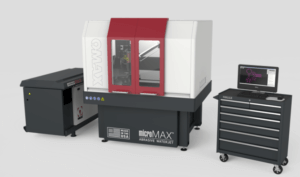

We are a select distributor of OMAX abrasive waterjet cutting machines — a global leader in the industry — well known for producing environmentally-friendly, affordable and easy-to-use waterjet cutting machines. OMAX develops complete waterjet systems with the customer in mind. OMAX has been an innovator in waterjet technology, propelling the industry ahead with the introduction of its IntelliMAX CAD/CAM software, motion control software and the first reliable high-pressure pump. In addition, OMAX offers the smallest footprint relative to the table size, thereby conserving valuable shop floor space – check out the OMAX ProtoMAX with compact dimensions of 56.5″ H x 41.5″ L x 39.5″ W.

OMAX designs, manufactures and tests each machine as a complete system before delivering to a customer. Check out the OMAX difference.