In the world of manufacturing, choosing the right machine tool can mean the difference between success and costly mistakes. Mills and lathes are two of the most commonly used machines in the industry, but their uses and benefits are often misunderstood. We will explore the basic differences between mills and lathes, helping you consider…

In the world of manufacturing, choosing the right machine tool can mean the difference between success and costly mistakes. Mills and lathes are two of the most commonly used machines in the industry, but their uses and benefits are often misunderstood. We will explore the basic differences between mills and lathes, helping you consider…

Keeping Your Parts Production Process Green Without Sacrificing Clean In Part 1 of the Clean & Green Industrial Parts Cleaning Series, we discussed Environmental Considerations for Green Parts Cleaning Solvents. In this article, we will focus on keeping your parts production process green AND clean. In an industry in which production time, volume, and quality…

Keeping Your Parts Production Process Green Without Sacrificing Clean In Part 1 of the Clean & Green Industrial Parts Cleaning Series, we discussed Environmental Considerations for Green Parts Cleaning Solvents. In this article, we will focus on keeping your parts production process green AND clean. In an industry in which production time, volume, and quality…

Environmental Considerations for Green Parts Cleaning Solvents If you are using legacy parts cleaning solvents, pending changes in state and federal law governing the use of hazardous parts cleaning solvents such as TCE, Perc, nPB, HFC’s, and others, WILL require you to rethink how your company can effectively meet your green parts cleaning requirements. A…

Environmental Considerations for Green Parts Cleaning Solvents If you are using legacy parts cleaning solvents, pending changes in state and federal law governing the use of hazardous parts cleaning solvents such as TCE, Perc, nPB, HFC’s, and others, WILL require you to rethink how your company can effectively meet your green parts cleaning requirements. A…

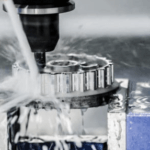

As more and more machine shops are competing for jobs throughout the world in the aerospace, medical, automotive and industrial markets, they need to find better ways of being competitive at the spindle. We all know that the market drives how much we can charge for our components and it’s up to us to increase…

As more and more machine shops are competing for jobs throughout the world in the aerospace, medical, automotive and industrial markets, they need to find better ways of being competitive at the spindle. We all know that the market drives how much we can charge for our components and it’s up to us to increase…

What is the proper break-in procedure on NSK electro spindles? If the spindles have been idle for some time, does the user need to warm them up before use? The NSK iSpeed3 Series is a high-precision, high-speed motor spindle. The following procedure must be followed to ensure proper motor spindle operation and longevity. The grease…

How can I safely get my 3-jaw chuck off my turning center? Lower the pressure down to minimum so actuation is slow. When you are in the middle of the stroke hit E stop. Now remove all bolts but one, leave that one on by a quarter inch and use the chuck wrench to take…