OMAX Abrasive Waterjet Cutting: An Ideal Addition to Any Machine Shop

Abrasive waterjet cutting machines of the past had lower water pressure and were relegated to cutting only soft materials. With the advent of the new narrower and more powerful high pressure jet streams, abrasive water jet cutting machines such as OMAX have earned a reputation as the preferred method of cutting heat sensitive materials. With OMAX waterjet machines, cut any material AND get a smooth finish. Water jet cutters offer lower costs and increased throughput, while maintaining the integrity and quality of the workpiece.

Abrasive waterjet cutting machines of the past had lower water pressure and were relegated to cutting only soft materials. With the advent of the new narrower and more powerful high pressure jet streams, abrasive water jet cutting machines such as OMAX have earned a reputation as the preferred method of cutting heat sensitive materials. With OMAX waterjet machines, cut any material AND get a smooth finish. Water jet cutters offer lower costs and increased throughput, while maintaining the integrity and quality of the workpiece.

How Does Abrasive Waterjet Cutting Work?

Water jet cutters hold a unique place in manufacturing – they use water as the tool to cut almost any material type and thickness. With water streaming through a narrow orifice at a rate upwards of 60,000 psi, it is in a league of its own. Water jets are fast, flexible and effective in meeting a wide variety of manufacturing applications.

Advantages & Benefits of OMAX Abrasive Waterjet Cutters

OMAX Abrasive high pressure waterjet cutting systems provide many advantages, including:

- Fast setup

- Easy programming

- High cutting speeds

- Narrow, precise cuts

- Safe to use in nearly any industry or type of material

- Low cutting forces, and therefore minimal fixturing

- It creates no heat-affected zones (HAZ) for cutting materials that are heat sensitive

- Airborne fumes and fibers are significantly reduced or eliminated

- With reduced kerf, parts can be positioned or nested closer together resulting in overall savings on materials

- It does not create burred or roughed edges therefore reducing or eliminating the necessity for secondary machining.

- Eliminates the distortion from compression that is created by traditional die cutting methods.

Over the years, waterjet cutting, a true competitor with high cutting force, high efficiency, FDA accepted sanitary statistics and a “delicate” touch, has proven itself in many manufacturing arenas. You’ll find waterjets in industries like food, textile, paper, armor plating, glass, rubber and foam cutting, among others, and of course metals and alloys parts manufacturing.

The OMAX Difference

Productivity’s line of OMAX waterjet cutters are highly eco-friendly. The can cut virtually any material type and thickness, have easy and quick setup and programming, and require simple fixturing. What was once a rough cutting tool is now a considered a precision machine tool, with capabilities ranging from macro- to micro-machining for many materials. OMAX waterjet cutting machines are capable of making high-precision complex 3D parts. Check out this OMAX blog on How to Make Good Part Drawings.

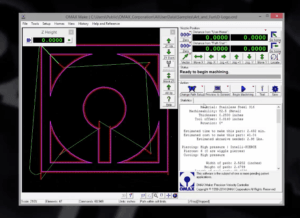

We are a select distributor of OMAX abrasive waterjet cutting machines — a global leader in the industry — well known for producing environmentally-friendly, affordable and easy-to-use waterjet cutting machines. OMAX develops complete waterjet systems with the customer in mind. OMAX has been an innovator in waterjet technology, propelling the industry ahead with the introduction of its IntelliMAX CAD/CAM software, motion control  software and the first reliable high-pressure pump. In addition, OMAX offers the smallest footprint relative to the table size, thereby conserving valuable shop floor space.

software and the first reliable high-pressure pump. In addition, OMAX offers the smallest footprint relative to the table size, thereby conserving valuable shop floor space.

Abrasive water jet cutters won’t replace your existing machining processes, but most every shop can benefit from a waterjet machine onsite. You can count on the waterjet process for a wide range of additional applications including prototyping, short-run jobs, cutting multiple parts from stacks of material, and complex cutting jobs to name a few.

Not sure if a waterjet is right for you? Ask Productivity about an OMAX feasibility demo of waterjet processing for your particular application before making the necessary capital investment.