PLUG-N-PLAY AUTOMATION PACKAGES

FLEXIBLE manufacturing systems. LOWER initial investment. SHORTER lead times. PREDICTABLE results.

ECONOMY PACKAGE-COLLABORATIVE

Collaborative, mobile part pick-and-place

Automate your part pick-and-place operations with ease using the Flex™ EP-C. This package includes a mobile platform, allowing convenient relocation of the entire automation setup. The platform provides safe, stable support for the cobot, its control cabinet, and the part pick-and-place table. The Flex™ EP-C utilizes the latest in automation technology, making its operation intuitive and straightforward.

- Lightweight system

- Simple & intuitive operation

- Safety packed design

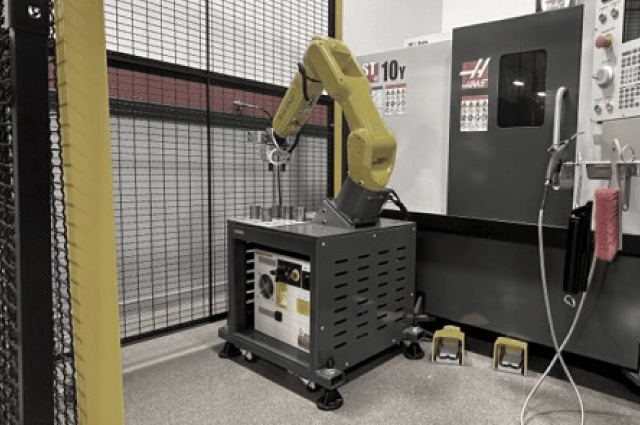

VALUE PACKAGE

Affordable, easy-to-operate palletized drawer system

Automate a single mill or lathe operation with the Flex™ VP. This compact, low investment, palletized drawer system can be floor-mounted or upgraded to a pre-mounted moveable platform, enabling the entire cell to move as one unit. Operating the Flex™ VP is simple and automatic once parts are placed.

- Floor or platform mounted

- Single machine only

- Mill or Lathe compatible

- Low cost system

- Compact footprint

GRID TABLE

Flexible table part queue system

Maximize walkaway time, at minimal cost with Flex™ GT. This simplistic system utilizes off-the-shelf components to reduce cost and lead time. With numerous steel, welded table sizes, Flex™ GT can accommodate wide varieties of queue potential and part sizes.

- Simplistic Part Queue

- Quick Change-Over

- Scalable

DOCKING SYSTEM

Space conscious palletized cart system

Achieve rapid material exchange for continuous production with the Flex™ DS. This compact production cell with built-in robotic part loading system features two independent docking frames and hydraulic scissor-lift transport carts for flexible orientation with the robot and machine tool. Each Flex™ DS transport cart is equipped with a 27.375” x 17.5” aluminum part pallet enabling the quick exchange of blank and finished parts.

- Compact footprint

- Mill or Lathe compatible

- Easy, fast changeovers

- Multi-machine layouts possible

CONVEYOR SYSTEM

Infeed/outfeed conveyor system

Automate part loading and unloading effortlessly with the Flex™ CS conveyor system. This versatile setup includes two conveyors with an integrated vision camera (above the infeed conveyor) and a robot securely mounted on a welded steel pedestal that secures to the shop floor.

To operate, parts are placed at random onto the infeed conveyor. The advanced vision system accurately identifies each part's location and orientation, transmitting this data to the robot for precise pick-up. Once processed, the robot seamlessly transfers completed parts to the outfeed conveyor for further processing or assembly.

- Most versatile system

- Multi-machine layouts possible

- Mill or Lathe compatible

- 1000 lbs. material capacity

- Heavy payload versions available

PALLET STATION

Floor-mounted pallet system

Automate part loading and unloading with the Flex™ PS. This system features two independent docking frames and two 40” x 48” engineered part pallets, enabling flexible orientation to both the robot and machine tool, and facilitating rapid material exchange for uninterrupted production. The robot is securely anchored to the shop floor via a welded steel pedestal. The Pallet Station hardware allows operators to swiftly and precisely manage the work queue.

- Ideal for large/heavy parts

- High-volume part queuing

- Multiple machine layouts possible

- Simple operation

DOCKING CABINET

Compact, high-volume vertical part storage system

Automate high volume part production and storage with the Flex™ DC - a compact production cell featuring a complete robotic part loading system. It includes one independent drawer cabinet with up to 6 vertically stacked drawers. Each drawer is equipped with 27.75” x 32.75” aluminum part pallets and 4.5" height spacing. Additional drawer cabinets can be integrated into the cell as needed. The robot is securely mounted on a welded steel pedestal that anchors to the shop floor.

Operating the Flex™ DC is straightforward: operators place part blanks on pallets carried by the drawer slides. As needed, operators can load and unload parts from each drawer accessed from outside the cell. The robot retrieves each drawer internally to handle parts throughout the manufacturing process. After quickly swapping pallets in each drawer, the cabinet is ready for the next job, ensuring automated processing until completion.

- Easy, fast changeover

- Suitable for larger, heavier parts

- Multiple machine layouts possible

- Simple operation

- Mill or Lathe compatible

FLEX FEEDER

Intelligent bulk flex feeder system

Bulk-feed parts into production automatically with the Flex™ FF - a compact robotic part loading system featuring an intelligent bulk flex feeder and vision-based robot-guidance system. Parts are dispensed from a pre-feed hopper onto a backlit pick-up area, where selectable feed cycles advance, separate, and flip parts for robot handling. This efficient setup optimizes floor space usage while allowing easy access to your machine tool for setup and maintenance.

Operating the Flex™ FF is straightforward: operators pour un-machined parts into the pre-feed hopper. The vision system coordinates the dispensing of a thin layer of parts onto the backlit pick surface, which can move forward, backward, or vibrate to separate parts. A programmed bottom strike flips upside-down parts as needed. The system continues processing parts automatically until depletion.

- Compact footprint

- Multiple machine layouts possible

- Intelligent operation

- Mill or Lathe compatible